-

Let's talk about your invention

Book Appointment

-

Inventor's Guide

Get your Guide now

Product Design | Industrial Design Center

Product design is a creative process where technical feasibility criteria for an invention, economic viability, and the aesthetics and ergonomics of the new product converge.

Inventors often have innovative ideas to improve existing products. In many cases, the outcomes of the product design process

The main goal of the product design process is to make decisions that enhance the inventor's idea

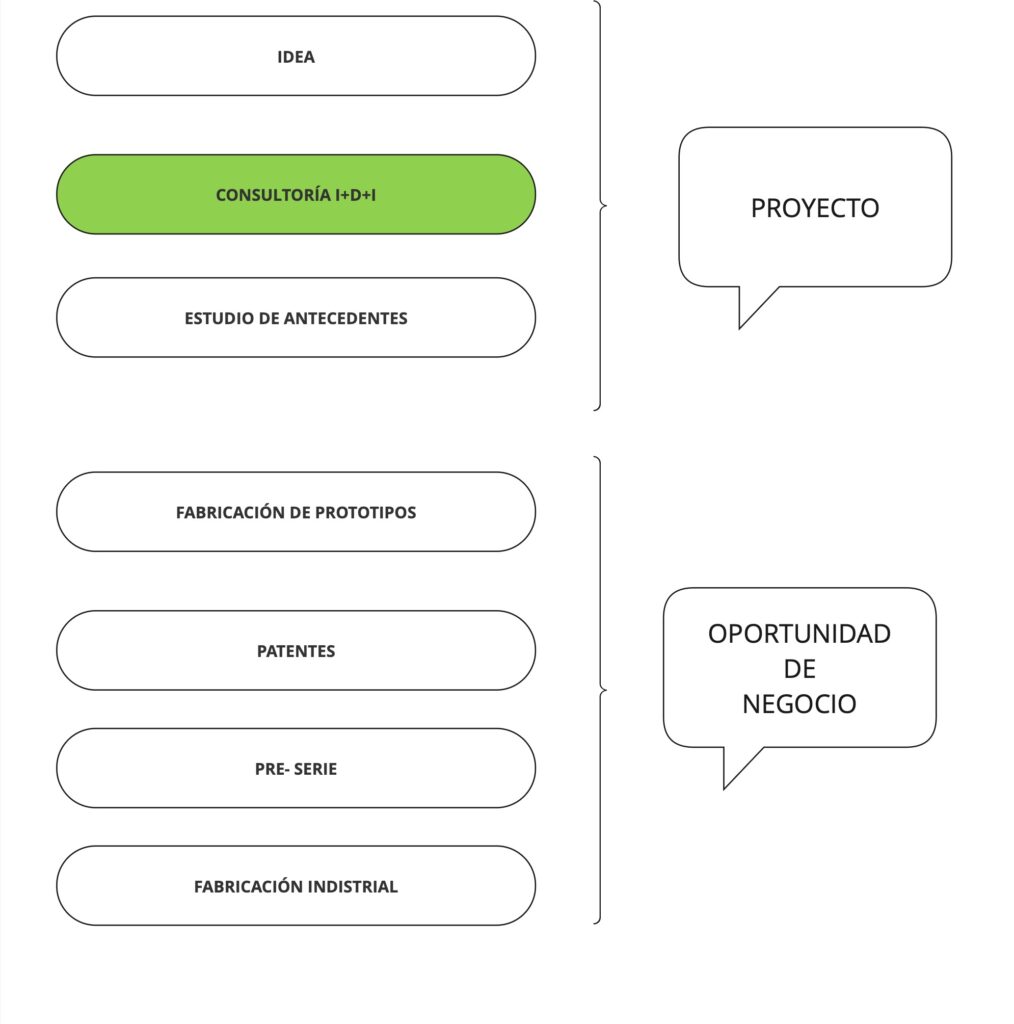

Product design is a process that plays a role throughout the entire innovation cycle. In some way, all product improvement decisions tend to impact design, regardless of the stage of product development.

El diseño de producto, forma parte indisoluble del servicio de consultoría i+d+i.

Product Sketches

Graphic representation of the idea. Definition of the main design challenges.

3D Modeling

Projection of solutions. 3D Modeling and digital operation simulation.

Do you want us to analyze your invention?

We will put all our resources into proving that your invention works.

The definition of sketches for an innovative product is the graphical representation of the idea. The product sketch does not aim to explain how it works but rather what problems it solves in the market.

The main purpose of a design sketch is to facilitate the communication of ideas and product concepts.

The process of industrial design for an innovative product is the cycle where the main solutions to the challenges and functional requirements of the invention are developed and defined.

In industrial product design, it is essential to keep in mind that inventions must become profitable, aesthetic, and ergonomic products.

The simulations of industrial design for innovative products are defined as an experimentation cycle with the digital prototype. Through digital tools, simulations are conducted to identify product design errors.

The optimization of design is a process that is activated at different stages of the development of an innovative product. It includes design optimization at an aesthetic level, functional improvements, reduction of parts and components, or geometric adjustments that influence the ergonomics of a product.

In addition to the blueprint notebook of the parts and components derived from the final design, it is common to prepare 3D renders and graphic designs of the products to enhance their commercial understanding.

Service details for product development

With the innovative product design service, we can define and graphically represent the details related to the product's functionality. Specifically, everything concerning structures, mechanisms, aesthetics, sustainability, and product ergonomics.

The process of innovative product design usually takes approximately 100 days. Its cycle is entirely linked to the R&D stage.

Blueprint notebook for parts and components.

Definition of materials for each part.

Videos or animated materials to demonstrate the operation of mechanical systems.

3D Files

Co-creation: We use the joint development method. This approach encourages the active participation of the inventor or promoting team. It is essential to stay focused on solving problems that the inventor understands better than anyone.

We work with 3D design software that enables the design of parts, integration, and simulation of the product's future behavior.

The design of innovative products is usually a service included in the R&D consulting.

Strategy for Designing an Innovative Product

At Let’s Prototype, we have a product design method based on breaking down challenges. Designing an innovative product or improving an existing product is a complex process, and making the best decisions for each part of the new product is key. Subsequently, we define the aesthetic line of the product’s exterior, considering ease of use.

5 Steps to Design a Product.

Problem Analysis

The process of product design must always start with an analysis of the problem it aims to solve in society. Based on this analysis, the functional requirements of the prototype are determined, along with the design details that could make the product competitive in the market.

Imagine we want to design a dog leash with a built-in liquid dispenser to clean areas where pets relieve themselves. According to the innovative product design method, we must break down the different challenges that make up the invention:

- What is the area that needs to be sanitized?

- What is the size of similar products in the market?

- What is the distance that the leash extension should allow?

- How much water should the product to be designed accumulate?

- At what temperatures will the invention be exposed?

- What mechanical strength should the product to be designed have?

- What is the water jet speed needed to achieve good cleaning?

Price analysis and product feasibility

Although the inventor sometimes forgets: the invention, besides being aesthetically pleasing and innovative, must also be economically viable. According to our innovative product design method, the second step is to define target prices. Even though designing and manufacturing a prototype is an early stage, there are decisions to be made in the design process that must be carefully considered:

- How much do the competitor's products cost?

- ¿Cuántos elementos de la industria podrían aprovecharse como partes del producto sin que se afecte la innovación?

- How optimized are the competitor's products?

- ¿Cuánto estaría dispuesto a pagar el cliente por la solución que se pretende proponer a través de un nuevo diseño de producto?

Definition of product parts and subsystems

Taking the previous example as a reference, before starting to design products, there are independent challenges that must be addressed separately:

- Purchase and testing of different retractable leash systems to evaluate prices and quality of this component. This will help assess the possibility of integrating an existing and industrialized mechanism into the product design.

- In the prototype laboratory, various fluid mechanisms would be tested to select electronic components and conduits that maximize space utilization and minimize costs while enabling the creation of an efficient product.

- Before finalizing the product design, we work closely with the electronics team to determine the dimensions of the resulting components. We conduct the same economic and availability analysis in the industry for the components that will make up the PCB design, batteries, charging systems, and other accessories.

- Phase of part design and mechanism design, including necessary accessories to ensure the product's functionality. In this stage, a material analysis will also be conducted to anticipate the prototype manufacturing process and the future industrialization of the product.

General product design

After verifying the product functionality in isolation, considering each individual decision and solution that shapes it, the product conceptualization will be carried out.

- Product Sketches: This is a freehand planning of the arrangement of the elements that make up a product. The goal is to define and validate the general product design, shapes, styles, and characteristics that, while maintaining an aesthetic and usability principle, ensure the functionality of the product. The product sketch is a useful and cost-effective tool to discuss its possible aesthetics after completing the engineering project of a product.

- Designing a Product in 3D: After reaching an agreement on the product sketch, the next step is to create a 3D design of the product. The 3D design allows the engineering team and the inventor to visualize how the prototype and the future product will look. The 3D design of an invention enables the inventor to conduct surveys and commercial tests to assess the potential market acceptance of the invention.

Product testing and improvements

The product design cycle usually culminates in the manufacturing process of a functional prototype. In the Let’s Prototype laboratories, prototypes are manufactured with the appearance of a final product. The purpose of the prototype is for the inventor to conduct functionality tests on the innovative product, leading to conclusions for improvement and design optimization.

We turn your idea into reality.

We can analyze your invention and identify improvements in the product design.

A proper product design can save a lot of money in the future industrialization process.

3D Printing and Product Design

The various 3D printing techniques have enabled significant advancements in developing new products. Specifically, 3D printing allows for continuous testing during product design, avoiding the high costs that could arise from changes in the product manufacturing process when it is already in the mass production or product industrialization phase.

3D printing allows for the manufacture and testing of parts that are part of the product design, without the need to invest in injection molds or other product manufacturing methods that typically cost thousands of euros.

Common Mistakes of Product Design Companies

Experience of Product Designers

While there will always be adaptations when industrializing a product, it's important for the product design team to have experience in mass production processes. This way, the inventor will have to invest less money in the industrialization process of the product.

Material Compatibility Study: In the realm of 3D printing, there are many technological advancements that allow for the manufacture of nearly any part with 3D printers. However, just because a part can be manufactured with the materials available for prototyping, doesn't mean that same part can be manufactured industrially. For this reason, it's crucial that when designing a product, a material compatibility study is conducted.

Reuse of Mechanisms and Parts

Product designers, by nature, are creative professionals. Often, designers overlook the importance of economic viability of the invention, so it's essential that in the product design process, industrialization experts and business development professionals participate, as they are the ones who will encourage the reuse of existing elements and mechanisms that can be integrated into the product design.

Continuous Testing:

ChatGPT The key to success in a product design process is continuous iteration and attention to challenges independently. Often, due to pressure or the inventor's expectations, fewer partial tests than advisable are conducted. To design an innovative product, it's necessary to conduct laboratory tests of each function independently and to disregard the aesthetics of the product in this cycle.

Electronic Product Design

Electronic product design, robot design, or appliance design doesn't have to be more complex than mechanical product design. From our experience, achieving innovative products where electronics aren't used, even though it may seem simpler, tends to be product design processes much more cumbersome and time- and money-intensive.

To create an innovative product with electronics, the key to success lies in the connection or integration of various engineering disciplines. In the early days of our prototype manufacturing lab, we focused on assembling a team of highly talented product designers and mechanical engineers. We developed electronic prototypes by collaborating with external teams specialized in PCB design and firmware programming. Eventually, our expansion as a product design company has demanded the incorporation of our own prototype manufacturing workshop, electronics lab, and software development team including mobile app development. This way, we work jointly and coordinatedly in the process of manufacturing functional prototypes.

Product design companies in Spain

Product design in Madrid

We have a laboratory for innovative product industrial design in Madrid. Our team of engineers can take your idea to the next level.

Product Design in Barcelona

We serve the inventor community in Barcelona. We work hand in hand with patent lawyers in Barcelona and leading companies.

Product design in Valencia

Specialists in industrial design and creation of functional prototypes with the appearance of the final product. We can help you!

Diseño de Productos en Alicante

Our team of industrial designers can accompany you throughout the process. We would be delighted to be part of this adventure.

Product design companies in the United States

Product Design in Miami

Product developers in Miami. IoT product design in Miami We can help you!

Product Design in Florida

Our team of industrial designers can accompany you throughout the process. We would be delighted to be part of this adventure.

The time to bring your ideas to life is now. We accompany you throughout the entire process: from idea to product.

San Juan Ingenieros, S. L, is the owner of the domain www.letsprototype.com, and in accordance with the General Data Protection Regulation (EU 1679/2016), we will process your data exclusively to handle your information request. You have the right to rectify or request the deletion of your data at any time via hello@letsprototype.com.