Industrialize a innovative product invention prototype

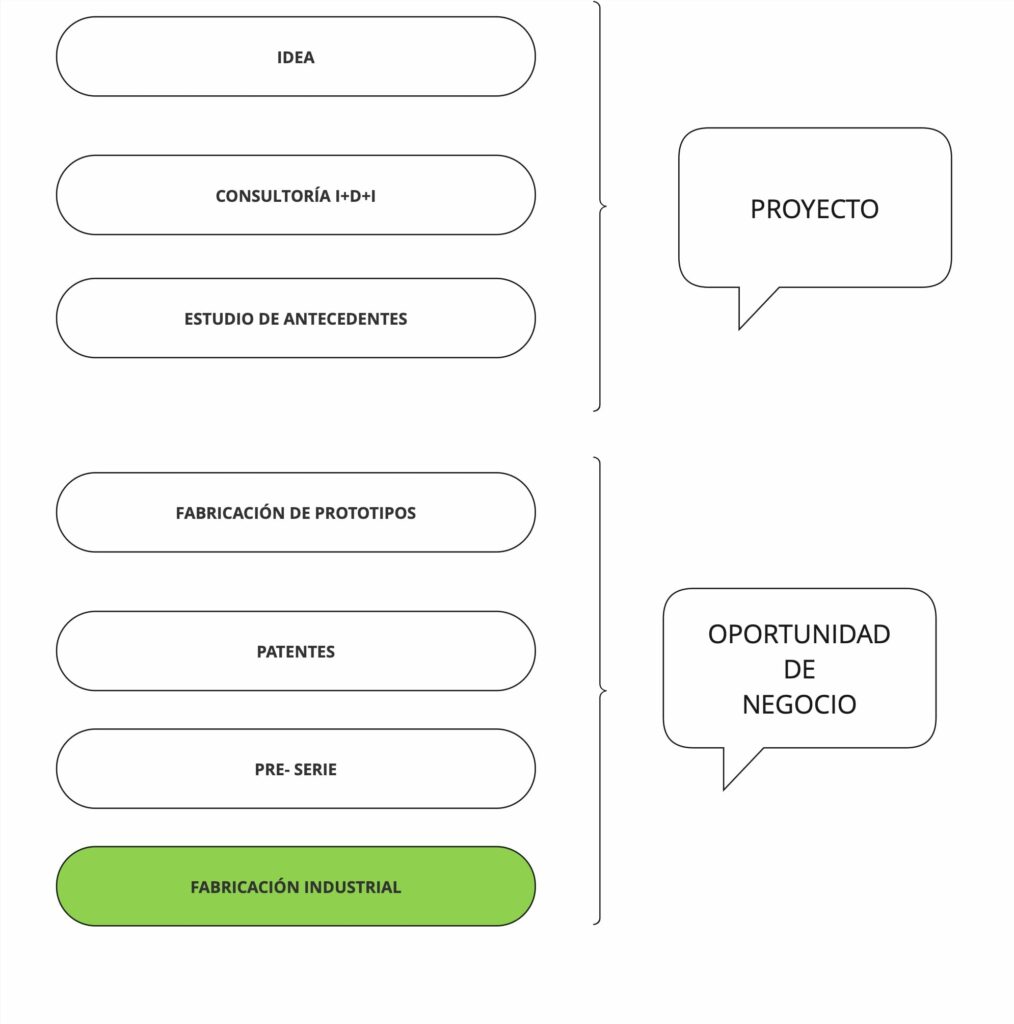

Pasos para conseguir la fabricación en serie de un producto innovador. Industrialización de prototipos.

-

Let's talk about your invention

Book Appointment

-

Inventor's Guide

Get your Guide now

Prototyping serial Manufactoring

Short Runs vs Industrialization of a Product

The mission of inventors is to transform an idea into a product ready for sale. Whether you intend to sell the product or sell the patent, you must understand the stages and steps to complete the process.

Short Runs: The processes of manufacturing replicas of functional prototypes are called pre-series or short runs. Once the functionality and appearance of the functional prototypes are validated, the prototype is replicated using non-industrial techniques. The goal of short runs or pre-series is to activate the patent sale process and learn about the product's usability. Short runs typically involve fewer than 200 units.

Mass production: This is the process of industrial manufacture of inventions. With the accumulated learning in the prototyping and manufacturing stage of short series, an adjustment process is carried out so that the product can be manufactured in series. In the industrial manufacturing stage, the main objective is to achieve mass production methods that are very cheap, so that the product reaches the market with sufficient economic margin.

First Prototype

Zero Unit of the Invention

Pre-series - Short Run

Handcrafted Replicas of the Functional Prototype

Industrialized Product

Mass Production of the Product with Applied Improvements.

Background of Mass Production for an Innovative Product

- Identify Technical Challenges of the Invention.

- Explore the best engineering solutions to develop a competitive product.

- Validate the Technical Feasibility of the Invention.

- Design the invention and integrate the components that make it up.

- Document the product development plan.

- Demonstrate that the idea works.

- Optimize the parts and pieces of the product thinking about the possible future techniques of mass production.

- Define a patent that captures all the learnings from the prototyping process.

- Show your product to potential investors or those interested in exploiting or buying the patent.

- Value the interaction users – prototypes.

- Have sufficient units to start the process of selling the patent, attracting investment or approaching factories to produce in series.

- Correct critical operational details that can only be discovered in a test process with real users/customers.

- Incorporate improvements that may result from the practical experiments conducted with the prototyped units.

- Prepare the design for industrial manufacturing.

- Adjust the invention according to current regulations, CE Marking, and the safety standards it must comply with, based on the target markets.

- To make manufacturing per unit as cheap as possible, to maximize the economic margins of the product.

- Activate 100% of the sales channels of the product.

- Maximize business opportunities with potential buyers of the patent or interested in exploiting it commercially.

6 Steps to Mass Prototyping

Mistakes in the industry are almost irreversible and very expensive. After a decade working hand in hand with Inventors, we can assure you that: every euro you save in the first Steps, will be multiplied by tens of thousands of euros in the later stages, which is where you really play the economic viability of your product in the market.

Step 1. Prototype design.

The design of the prototype is divided into two stages, in the first the concepts of the inventor are expressed graphically to align interests and product vision. The second stage includes a product optimization work that will have a high impact on the future profitability of the product, which is, in short, what investors and potential buyers of your patent will value you.

Step 2. Manufacture of the functional prototype.

Taking as reference the industrial design defined and validated in the first stage, the parts and pieces will be manufactured using handcrafted pieces. The first objective is to demonstrate that each part works correctly and then integrate them and form the first version of the your working prototype. It won't be perfect, but it's a critical step. It's the first time you'll be able to "touch" your idea.

Step 3. Manufacture of the functional and aesthetic prototype.

Although in the previous stage, the main operating hypotheses are validated. The truth is that the process of evolution of the first models to a prototype version that, in addition to meeting the expectations of operation, is aesthetic and apparent to be a final product is critical. Along with the delivery of this version of the prototype, all the necessary documentation is delivered to be able to replicate it.

Step 4. Manufacture of the pre-series or short series.

Before investing in the process of adaptation to factories with the capacity to reproduce the product in thousands of units, you will surely want to make sure that customers accept it, know how to use it, or have the necessary units to present your prototype to private investors, potential interested in buying your patent or industrial partners to take the project to the next level. Short series do not usually exceed 200 units.

Step 5. Adaptation to the industry.

The process of adaptation to the industry includes two stages. First, potential factories are identified based on the compatibility between their manufacturing capacities and needs, unit price and logistics costs. Once the right partners have been chosen to undertake the mass production of the product, the necessary technical adjustments are made so that the parts and pieces can be replicated in thousands of units automatically.

Step 6. Mass Production. Industrialization

After obtaining the first samples of the product, manufactured industrially, it is essential to carry out tests to validate the quality of the result. Subsequently, the product will be ready to be commercially launched in the target markets that are convenient.

Techniques for Industrializing Products for Mass Production.

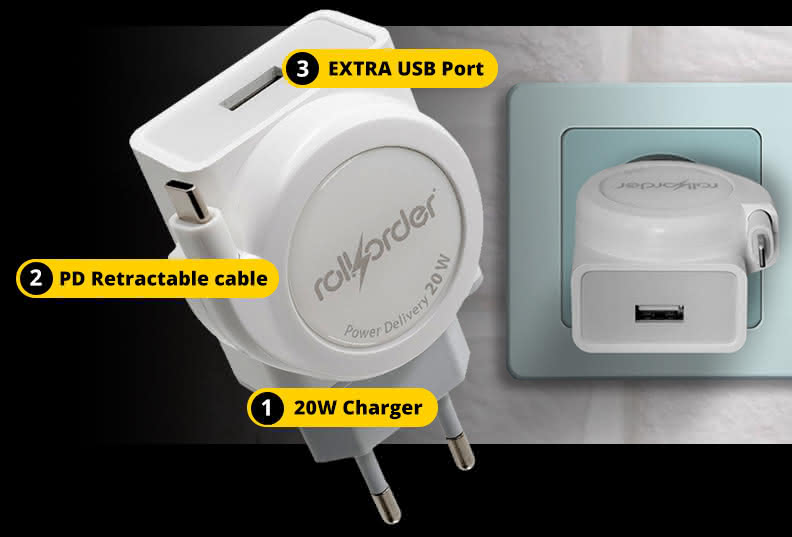

Mass Production of Electronic Products.

Component assembly: Component assembly is a process in which electronic components are placed and welded onto a printed circuit board (PCB). This can be done manually or automated by assembly machines, such as pick-and-place machines, which place components in the correct positions and weld them to the PCB.

Solder: Solder is used to attach the electronic components to the PCB. Different welding methods are employed, such as reflow soldering, in which heat is applied to melt the tin and join the components, and wave soldering, in which the PCB is immersed in a wave of molten tin to solder the components.

Encapsulation: Encapsulation is the process of protecting electronic components by applying a protective cover, such as epoxy resin or plastic, around them. This helps protect components from moisture, dust, and physical impacts, and also provides electrical insulation.

Testing and quality control: Testing and quality control are essential techniques in the industrialization of electronic products. Functional testing, performance testing, and durability testing are performed to make sure electronics meet quality standards and perform properly before being shipped to market.

Final assembly: Final assembly involves the integration of all electronic components and assemblies into a housing or chassis. This may include assembling displays, keyboards, batteries, connectors and other items, as well as conducting final tests to ensure proper operation of the entire product.

Production of plastic products

Rotomolding Manufacturing Technique: It is a process of pouring plastic powder into a structured mold. Once the powder is introduced, the temperature is raised to achieve the desired material properties while the mold rotates continuously. Then, the mold is cooled and opened to extract the formed part.

Plastic Injection Techniques: Plastic injection is one of the most widely used mass production techniques. Using a mold or die, typically made of steel, the molten polymer is injected inside to obtain the desired part within the mold.

Piece Manufacturing Technique by Extrusion: Extrusion is a technique where polymers are also injected at high temperatures to form parts from a die. However, instead of forming the part, cooling the mold, and extracting it, a continuous injection is performed while creating a continuous product with the desired geometry.

Vacuum Manufacturing Technique: It involves compressing a sheet inside molds or dies. This technique allows for the mass production of the interior linings of parts.

Mass Production of Metal Parts

Metal Cutting: Cutting is a technique used to separate metal parts into desired shapes. Various tools, such as saws, laser cutting, or plasma, are used to remove excess material and achieve the required shape.

Bending Method: Bending is a technique that shapes metal sheets by applying force to bend them into specific angles. This is achieved using bending machines that apply pressure and manipulate the metal to obtain the desired shapes.

Welding: The welding technique is used to join metal parts by melting or pressing the materials. There are different welding methods, such as arc welding, spot welding or laser welding, which allow to create strong and durable joints.

Metal Machining: Machining is a process through which metals are shaped by removing material using cutting tools such as lathes, milling machines, or drills. This technique allows for obtaining metal parts with precise shapes and high-quality finishes.

Shearing: Shearing is a technique used to cut metal sheets by using shears. These tools apply a concentrated force on a cutting line to separate the material and obtain parts with clean, straight edges.

Metal Stamping Methods: Stamping is a technique that involves pressing a metal sheet with dies to achieve specific shapes and patterns. By applying force, the metal sheets are deformed, creating components with precise and repeatable details.

Metal Casting: Casting is a process in which metal is melted and poured into a mold to create a specific shape. Once the metal cools and solidifies, it is removed from the mold, resulting in metal parts with complex shapes and consistent mechanical properties.

In the mass production process, there are no shortcuts.

Committed to the Inventors

Need to talk to an advisor?

In the process of mass manufacturing a product, there are no shortcuts. We describe the main risks of taking these steps early.

How much does it cost to industrialize a product?

The process of transition from the prototype to the final product, industrialized and ready to be reproduced thousands of times automatically, can be more or less expensive depending on the quality with which the functional prototype has been raised.

According to our experience, the integration of the engineering disciplines involved in product development, as well as the experience in transition processes from “prototypes” to “mass production”, are the factors that most influence the cost of the product industrialization process.

Integration of Engineering Disciplines: For example, in a prototype of an IoT industrial machine, it is essential that the design, electronics, telecommunications, and mechanics departments work side by side in the same environment, where they can materialize their work and think about the integration of results. It is very common for inventors, to save money at this stage, to hire inexperienced companies in these processes or, worse yet, try to manufacture it with independent professionals who do not work in the same space.

Considering these variables, we have witnessed product industrialization processes that are very similar, with comparable costs, precisely because of how the industrialization process was planned from the prototype stage.

This topic is closely related to the process of attracting investment or selling the patent. Private investors or large brands that might purchase the exploitation rights of your patent will assess, in the prototype, how closely it aligns with a future industrialization process, a variable that significantly impacts the price of the transaction.

The time to bring your ideas to life is now. We accompany you throughout the entire process: from idea to product.

San Juan Ingenieros, S. L, is the owner of the domain www.letsprototype.com, and in accordance with the General Data Protection Regulation (EU 1679/2016), we will process your data exclusively to handle your information request. You have the right to rectify or request the deletion of your data at any time via hello@letsprototype.com.