5 steps to get your prototype manufatured

We will list the requirements that must be met in the process of manufacturing working prototypes..

Within 72 hours, you will have a firm quote. With whatever amount we indicate, we assume responsibility for meeting 100% of your prototype’s working requirements..

Once the manufacturing process for your working prototype has been greenlighted, you’ll receive the work schedule and timeline. Each week, you will check your working prototype’s manufacturing status.

The requirements list will now become a “checklist.” Together, we’ll check that 100% of the functions have been successfully delivered. We are committed to doing so as efficiently as possible.

Some Prototypes delivered

Health sector Prototype:

Biocompatible materials

Cold moulding manufacturing

3D Design

SLA 3D Printing

Manufacturing by thermoforming

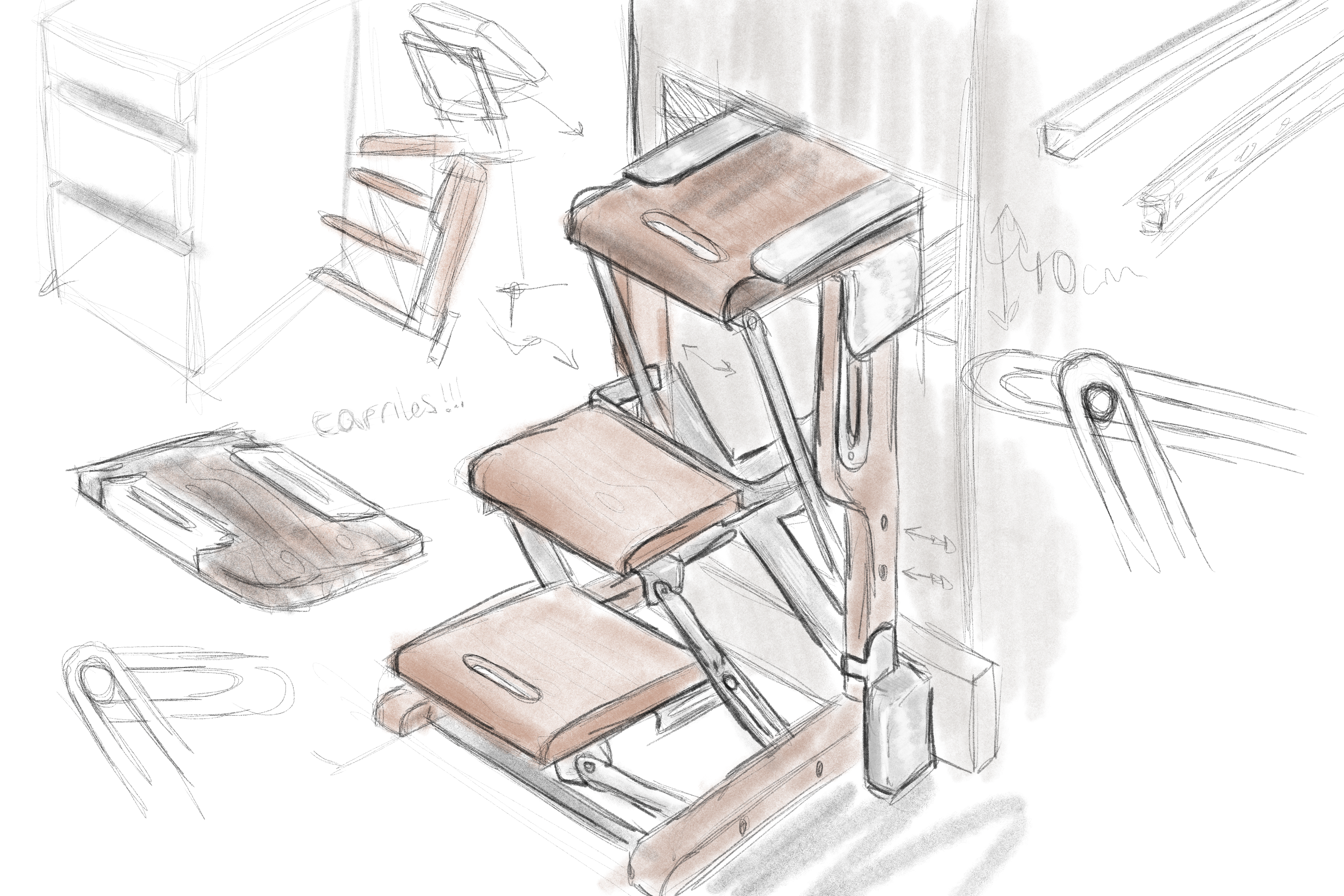

STEP(STAIR?) with legs

Prototype furniture industry:

Mechanical engineering

3D Design

Machining

3D Printing

The requirements of dismension and user experience, made it an excellent challenge.

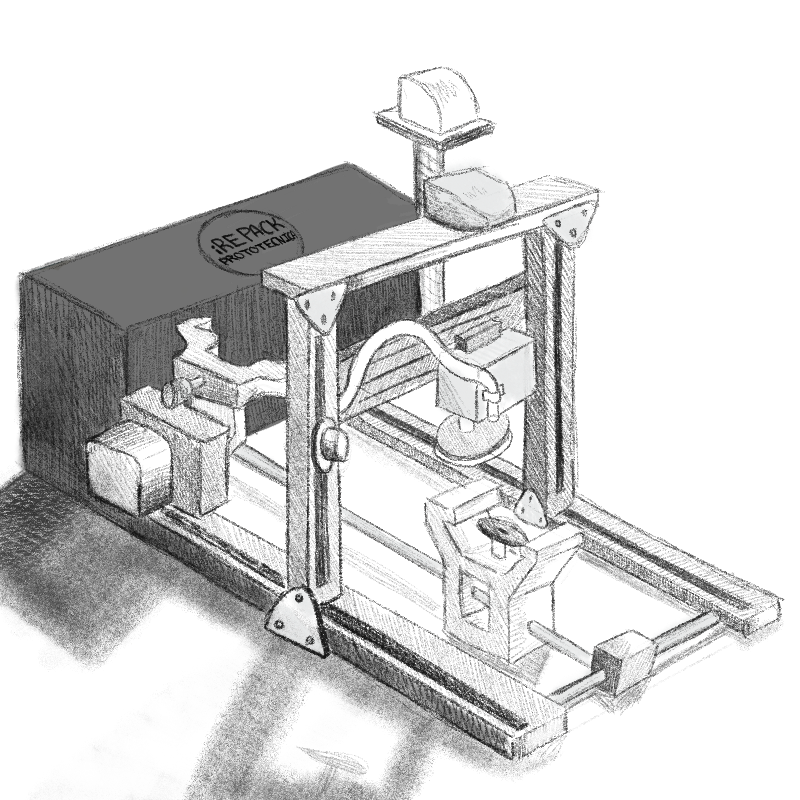

Robot Clean Mobiles

Robot Prototype:

PCB Design

PCB Manufacturing

Electronic design

Mechanical engineering

3D Design

FDM 3D Printing

Machining

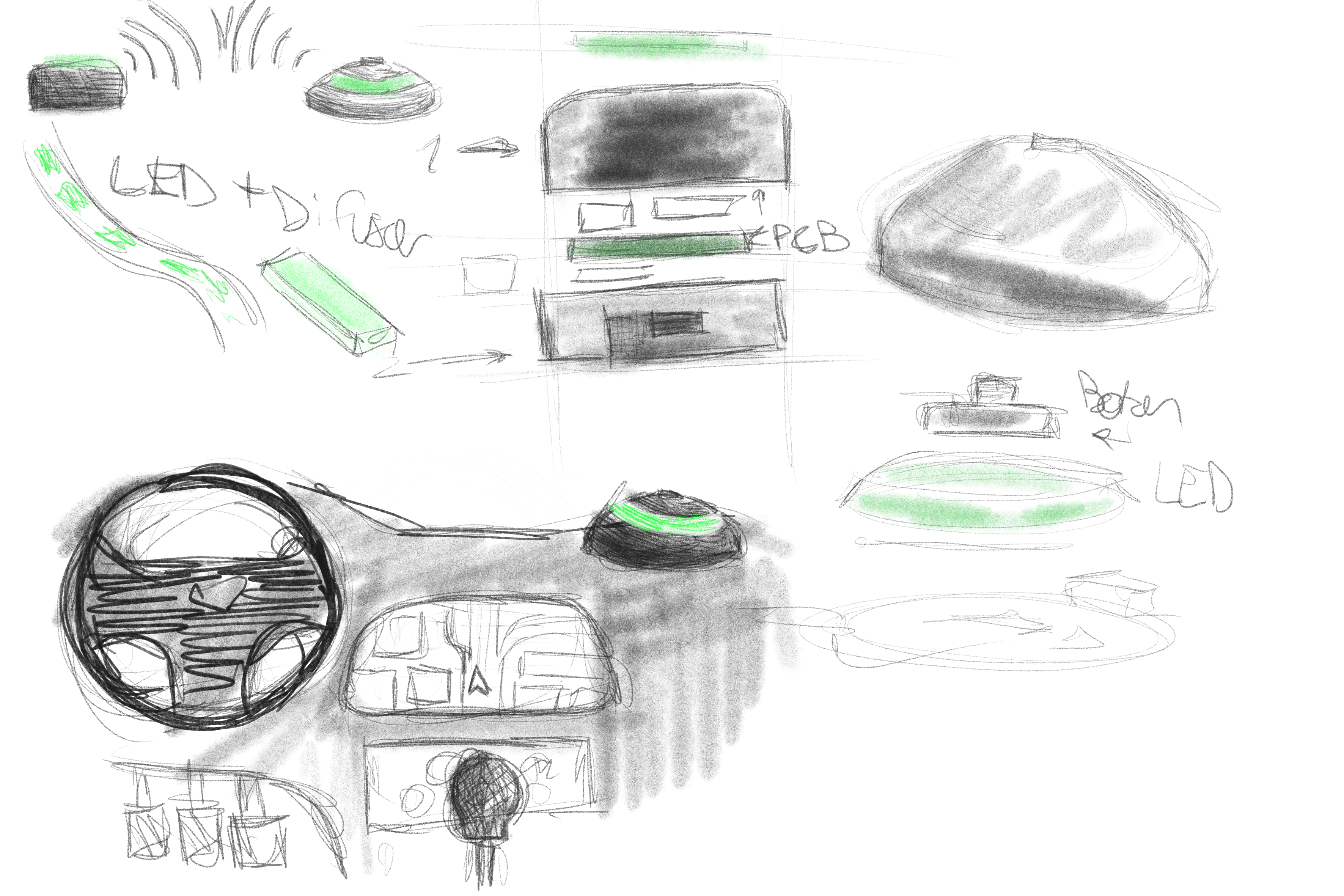

Baliz-e

IOT Product Development:

PCB Design

PCB Manufacturing

Electronic circuit design

3D Design

FDM 3D Printing

Machining

Software Development

Mathematical Models

Learning to detect dangerous falls, through a mathematical model and the development of an artificial intelligence protocol, made us enjoy the challenge.

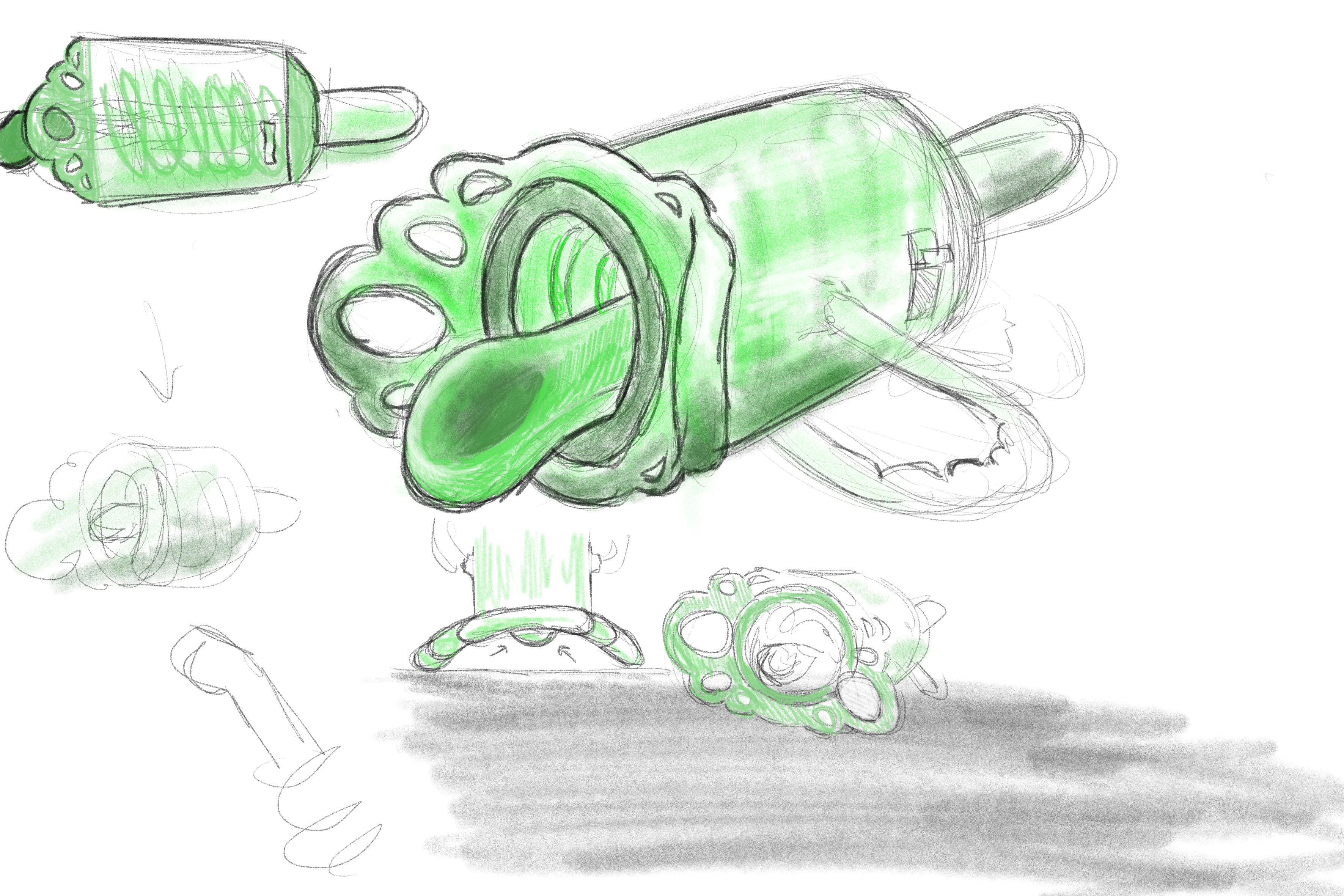

Pacifier

Prototype furniture industry:

Mechanical engineering

3D Design

3D Printing

Materials research

We’ll demonstrate that your idea works

Specializing for over 15 years in the manufacture of working prototypes

01

Digital validation

Based on your vision, we’ll design and simulate your idea’s main functions in digital environments.

02

Manufacturing your prototype

We will manufacture and iterate as many times as necessary until we demonstrate the technical viability of your prototype.

03

Checking that it works

Using as a benchmark the working requirements list shared during the retaining process, we will check each and every detail.

Other Prototypes

Here are some examples of products manufactured in our laboratory. Already patented and in Marketing processes.