HOW MUCH DOES IT COST TO PATENT AN IDEA?

Servicio de prototipado rápido

Steps to make a product prototype prototype of an invention prototype of an idea

Let's talk about your invention

Book Appointment

Get your Guide now

Creating a Prototype: What Is It?

Creating a product prototype is a process that consists of two main stages: Research & Manufacturing. Mixing these stages minimizes the chances of the invention's success in the market.

R&D Consulting: Se refiere a la etapa de identificación y solución de los principales retos técnicos del invento. Todas las ideas innovadoras, por sencillas que parezcan, requieren un ciclo de investigación y desarrollo para obtener propuestas competitivas.

Manufacturing: Creating a prototype requires the application of creative artisanal techniques that demonstrate the functional capability of an invention or any type of technological solution.

Details of the Product Prototype Creation Service

Objective

The motivations for creating a product prototype can vary. The most common ones include securing funding, protecting intellectual property, and measuring market acceptance.

Time

The product prototyping process usually takes between 3 to 6 months. The timelines for creating a prototype vary depending on the results of the R&D service and the technological complexity involved.

Delivery

Along with the first prototype of an invention, updated blueprints, 3D designs, manufactured PCB designs, firmware, and other necessary elements are provided to ensure the prototype functions properly.

Comunication

The integration of technical disciplines determines the quality of functional prototypes. Changes and updates during the prototyping process impact the entire development. Prototyping laboratories must include critical engineering areas such as Design, Mechanics, Electronics, AI Development, and more.

Tool

Industrial design software, artisanal manufacturing methods for parts, electronic circuit design systems, and the necessary programming tools are essential for creating a prototype.

Price

Creating a functional prototype doesn’t have to be excessively expensive. The quality of the preceding research influences its cost. Calculate the cost of a prototype.

Do you think you need to create a functional prototype? Let’s talk about it.

Useful Information for Creating a Prototype.

STEPS

TYPES

PRICES

STEPS

Creating a prototype involves 7 fundamental steps, ranging from technical research (R&D) to the prototype manufacturing.

Altering the order of the steps to create prototypes leads to a waste of resources while compromising the quality of the resulting prototypes.

TYPES

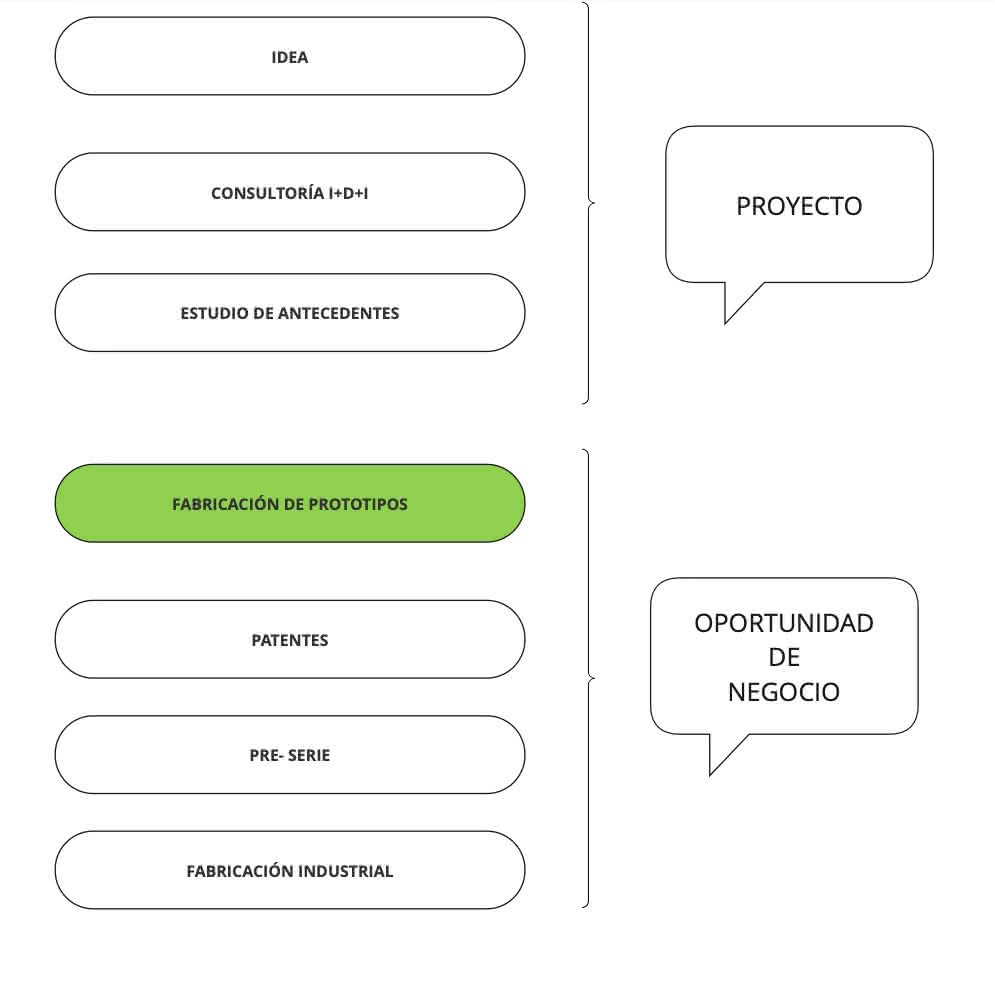

El desarrollo de un invento transcurre por tres etapas fundamentales: Idea, Oportunidad y Negocio. En función del estado de madurez de cada proyecto, necesitarás prototipos únicos para objetivos distintos.

PRICES

Hacer un prototipo funcional no es ni barato ni rápido. El precio de un prototipo funcional puede estar cerca de los 20.000 €. Ahora puedes calcular el precio aproximado para hacer un prototipo.

Steps to Create a Product Prototype

Steps to build a prototype with chances of success.

- Measure the problem: Creating a prototype for an innovative product only makes sense if it solves a market problem. Otherwise, it’s a work of art and not a product prototype that will, in turn, become a successful business. Make sure to measure the impact of the problem you have identified.

- Writing use cases: The use case of a product is the document that summarizes how the inventors envision the final product. It not only refers to the product's appearance but also to the prototype’s behavior in all possible situations. The process of writing use cases is, in itself, a reflective cycle that leads to important conclusions about desirable functional requirements and the technical challenges associated with the idea.

- Architecture definition: The architecture of a prototype is synonymous with solutions. Each of the use cases defined in the previous stage must find a response in the proposal of technical solutions, that is, in the architecture definition.

- Design validation: As part of the research stage, it is essential to create the first approaches to prototype design. In many Spanish prototype manufacturing companies, the mistake is made of sharing product designs with the client before writing the use cases for a prototype and defining its architecture. Rushing this process is often a major cause of frustration. The architecture of a product prototype defines the "guts"

- Prototype manufacturing: Manufacturing a prototype is the stage of consolidation and practical validation of the proposed solution at the engineering level. Even after completing the previous steps, there is still a certain level of risk, which is natural in the transition from theory to practice. The only way to reduce the cost of prototype manufacturing without compromising quality is by not violating the time and rigor required in the previous steps.

- Use validation: There is no prototype that satisfies 100% of the customer's needs in its first version. If you manage to create the perfect prototype, it is not a prototype, but a final product, and you have arrived too late to the market.

- Prototype optimization: By eliminating the romantic ties between the inventor and their invention, it is key to document the areas of improvement for the prototype based on user feedback when interacting with it. This input is critical to enhance the prototype and correct critical flaws before it is too late.

Common mistakes in the prototype creation process.

Experienced inventors or innovation departments of companies we work with have learned very relevant lessons in the prototype creation process of a product. Adding this experience to that of our team in the prototyping lab in Madrid, we have identified the 5 most common mistakes that doom novice inventors or entrepreneurs when trying to create a new prototype.

- Creating a prototype without a real problem: The ego of believing that the idea will change the world causes novice inventors to waste a lot of money on unnecessary steps to create a prototype. For example, most invest in utility models and invention patents before fully defining all the innovation.

- Avoiding market feedback: The ego and love for the idea motivate inventors to spend too much time in the lab prototyping products. Perfection is not achieved in the prototype. The real goal of a prototype is to clear technical and business hypotheses that determine the success of the future business.

- Saving money on research: Everything you save in the research process and defining the "How" will work against you when competing in the market. Most inventors believe that engineering is a superfluous expense, and only the prototype matters. Skipping stages of the method for creating a prototype only reduces the chances of success.

- Industrializing too soon: Rushing is never good, and in the cycle of creating a product prototype, it’s even worse. Industrialization is a necessary stage in the development of an innovative product, but arriving at it too early will lock your product into methods and components that probably aren't the best for competing in your market. Healthy product industrialization can only be achieved if the product has been designed and validated in an environment that understands the industry but is not committed to it. This is why prototyping labs exist.

How to make a product prototype online?

It is possible to make a product prototype online, but it is highly discouraged. The steps to make a prototype require coordination, communication, and interdependence. Decisions made at the mechanical level affect electronics, those in electronics affect the mathematicians, and the mathematicians affect the programmers, etc. The more disciplines or technical areas involved in the development of a product prototype, the worse the results will be if you decide to create a prototype with online tools.

Why should I know the steps to make a prototype?

To achieve any goal in life, whether personal or professional, we go through processes. These processes consist of consecutive challenges that, when viewed in perspective, make perfect sense.

When we achieve goals quickly, without this step-by-step process, we run a significant risk of losing what we’ve gained.

The same applies to creating a product prototype. If we take shortcuts or skip important steps, we’re likely to end up with a prototype that has limited chances of success.

What are online prototyping platforms used for?

Online platforms for hiring professional services for prototype development are useful for finding support in technical areas that are not critical in the prototyping process. For example, if we are developing the prototype of an innovative machine with complex metal components, we do not need to manufacture all the parts ourselves or have the necessary technology to do so. We could hire an external prototype manufacturer specialized in laser cutting and request these prototype parts. The key is not to outsource the critical areas of a product prototype.

Can I create a prototype in China?

The prototype creation process should take place in a controlled, confidential, and creative environment. In China, you can get the best prices to manufacture a product and make it profitable. However, manufacturing prototypes in China carries more risks than benefits.

Do you want to turn your idea into a product?

The time to bring your ideas to life is now. We accompany you throughout the entire process: from idea to product.

San Juan Ingenieros, S. L, is the owner of the domain www.letsprototype.com, and in accordance with the General Data Protection Regulation (EU 1679/2016), we will process your data exclusively to handle your information request. You have the right to rectify or request the deletion of your data at any time via hello@letsprototype.com.

Valorar este page