We want to bring your ideas to life

CATALOG OF

PROTOTYPES

You can now access over 30 examples of prototypes designed and manufactured in our lab

In the case of electronic prototypes, we identified that one of the main concerns of inventors is being able to contact manufacturers in China capable of mass-producing thousands of printed circuit boards (PCB). While this step is probably very relevant and essential for the health of the future business, prioritizing this contact and hiring process before developing electronic working prototypes is tantamount to dooming your project to failure.

We want to bring your ideas to life

You can now access over 30 examples of prototypes designed and manufactured in our lab

Remember that the objective of a working prototype isn’t just to demonstrate technical feasibility, in the design and manufacturing process it’s key to iterate and learn enough to be able to ascertain the best operating and future manufacturing approach.

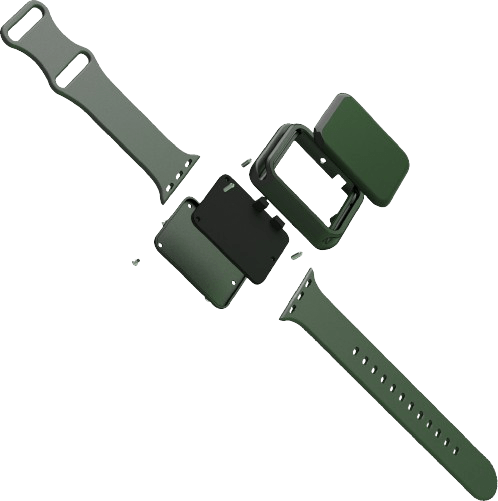

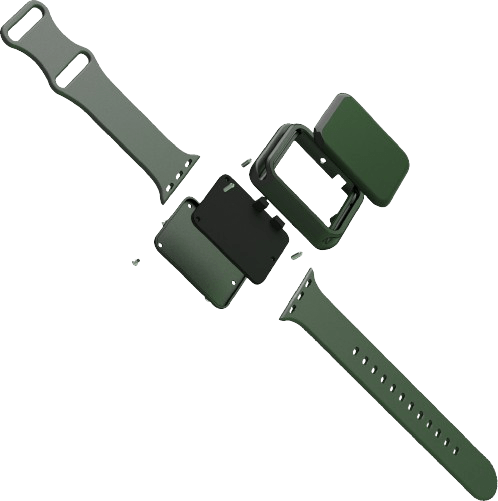

When it comes to electronic prototypes, at Let's Prototype the first thing we do is analyze the electronics required for the prototype, in order to subsequently develop the circuits on paper and in digital format. Yes, you read that right: we draw the different logics or circuit diagrams on paper. That way, the entire team of experts in the field can give their opinions on the optimal ways to arrive at a solution. This phase includes selecting electronic components, as it’s important that the engineering team identify any components that are widely available in the marketplace, fulfill your prototype’s needs and ensure that the options be economically feasible. It’s a difficult balancing act, but it’s what we do.

Before manufacturing the first board, experiments are conducted with cables and components on a protoboard to detect any possible failures or incompatibilities among the components selected. In this phase, we achieve the electronic functionality of the prototype, polishing all the details so it behaves as expected.

Once the finished circuits are ready, we devote ourselves to designing the printed circuit board, minimizing the size of the electronics. At this point, we can manufacture the first unit by engraving the circuit on a copper board, applying the anti-weld resin and welding the components.

After completing the manufacturing process of the first unit, we go on to the prototype testing phase. This stage usually leads to the aesthetic redesign of the prototype, allowing its parts to be smaller and more compact.

Encontrarás miles de opciones para fabricar tu placa o PCB en serie. Podrías ir a China u otras industrias donde los precios para productos fabricados en serie son muy competitivos. En cambio, es muy probable que necesites, antes de este paso, tiradas cortas o pre series que te permitan validar el producto en el mercado, mostrarlo a inversores o a potenciales socios industriales interesados. En este caso, Let’s Prototype sigue siendo tu aliado ideal. Si necesitas hacer entre 10 y 100 placas electrónicas, podremos hacerlas en nuestro laboratorio, con total garantía. En caso de necesitar más de 100 y hasta 10.000 unidades, podremos pedirlas a socios estratégicos de Let’s Prototype .

Now, then, should a large quantity of units be needed, the PCB can be produced in mass quantities with an outside partner.

Remember that, when selecting a company to manufacture your prototype, it is important that the areas intervening in the design and manufacturing be members of the company’s staff, thus guaranteeing that they will work together to achieve more efficient, functional and aesthetically-pleasing prototypes.

If you’re interested in learning more about our methodologies for manufacturing electronic prototypes and other working prototype typologies, you can schedule a call or continue reading our Tips.

The time to bring your ideas to life is now. We accompany you throughout the entire process: from idea to product.

San Juan Ingenieros, S. L, is the owner of the domain www.letsprototype.com, and in accordance with the General Data Protection Regulation (EU 1679/2016), we will process your data exclusively to handle your information request. You have the right to rectify or request the deletion of your data at any time via hello@letsprototype.com.

Industrial design and innovative product development company | Specialists in manufacturing working prototypes.