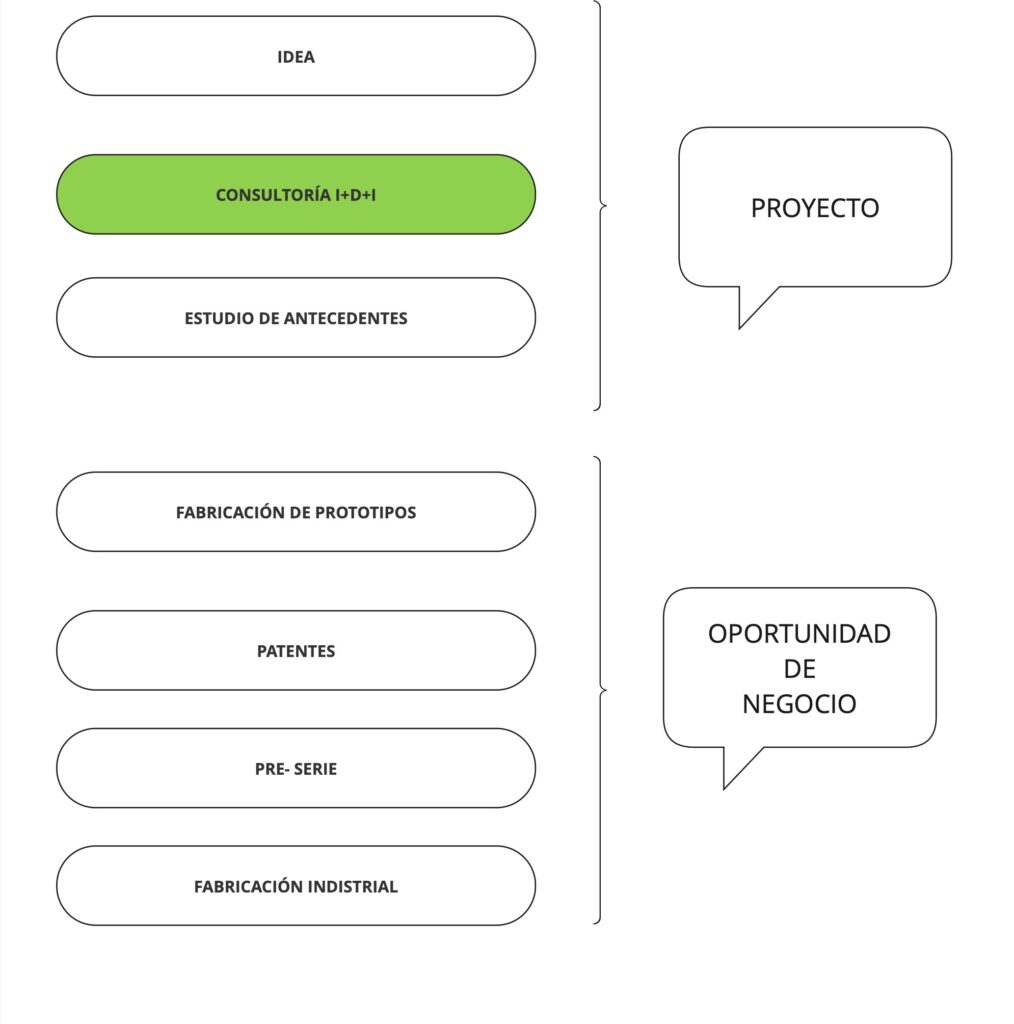

The first stage of R&D consulting consists of the identification of technical challenges that impact the technical and economic feasibility of your ideas.

All innovative products, no matter how simple they may seem, hide technical challenges that must be addressed individually.

The way these details are addressed is often closely linked to their chances of success in the market.

We will think outside the box with you to find the best alternatives.

The mechanical design process in the R&D consulting cycle involves representing alternatives to meet the functional requirements determined by the inventors, as well as addressing the main hypotheses.

This design cycle will allow for verifying, before manufacturing the first prototype, the technical feasibility of the product.

It is not a superfluous expense, nor an unproductive period. The investment in design during the R&D phase of a product helps minimize future costs of prototype manufacturing and the product to be industrialized.

Experiments in the R&D consulting process are isolated tests that allow us to demonstrate the technical feasibility of the proposed engineering solutions.

Example: If we are going to build a machine to squeeze lemons, before completing the design, selecting motors, screens, or shapes, it is essential to test alternatives that allow extracting the juice using the least amount of energy possible.

The juice can be extracted by compressing the caps, rotating a piece inside, or rotating the lemon cap against the piece. Which method is the most efficient?

Skipping the experimentation stage in the R&D process jeopardizes the chances of building an innovative product with real opportunities for success.

When R&D consulting is taken seriously, it is almost impossible to find the best solutions with the first proposal.

We will update the design and approach to engineering solutions as much as feasible to achieve a product proposal with high chances of success.

The final documentation of the R&D consulting process for product development includes the answers to the main identified technical challenges.

Includes:

- Detailed explanation of the experiment cycle.

- Achieved results.

- Comparison of technical proposals.

- Integrated product vision, useful for the prototyping phase.

We usually accompany the R&D consulting document with small models that provide physical proof of the invention's feasibility.