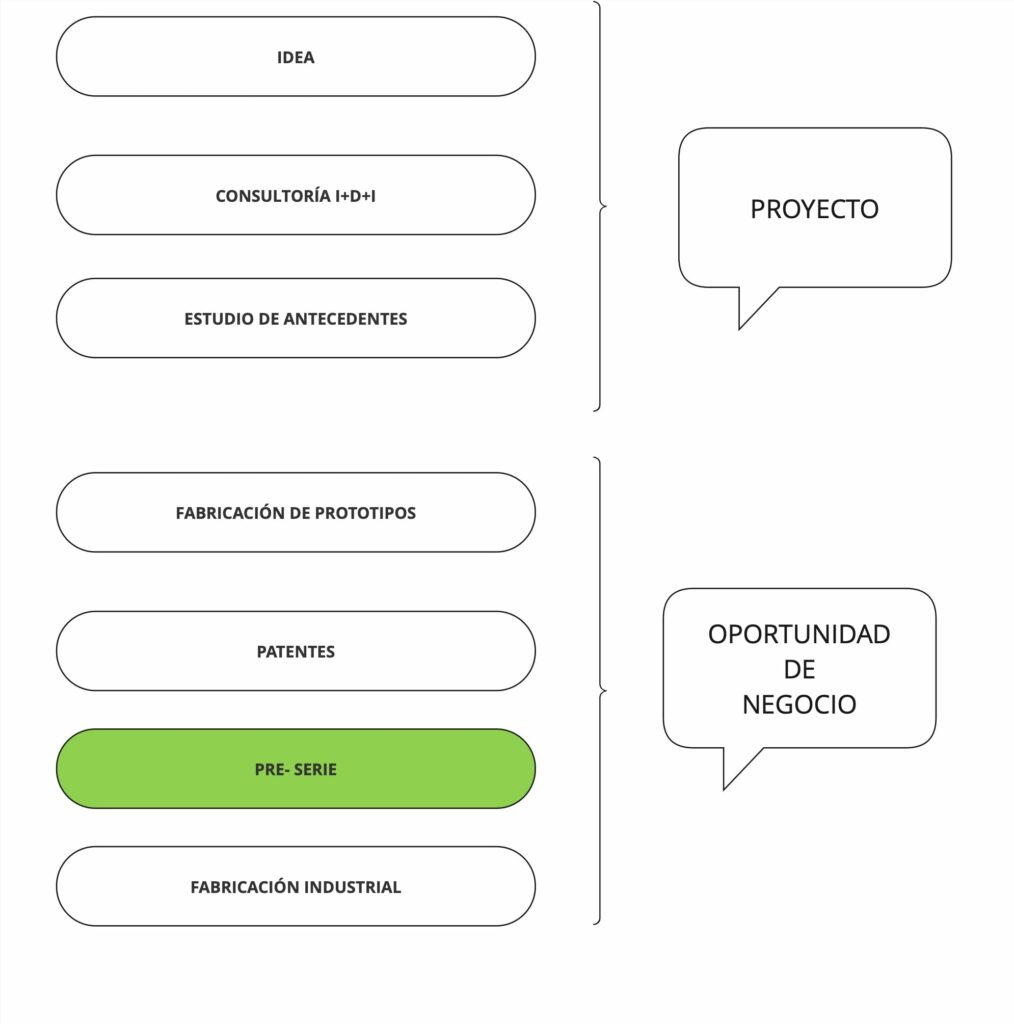

Before building pre-series units of an innovative prototype, it is critical to define its objectives. Essentially: quantify the sample and details of the experiments to be conducted. Define a method for observing and documenting the results. List the main hypotheses we aim to prove through the use of the pre-series units.

At Let’s Prototype, we can help you design the experiment plan to mitigate risks in the future industrialization of the invention.

The pre-series manufacturing techniques must be flexible. It is important that changes can be made and applied during the testing cycle. For this reason, large investments are not justified for manufacturing pre-series units of a product.

- 3D Printing

- Silicone Molds

- Plastic Mold Manufacturing with Thermoforming.

- Handcrafted PCB Manufacturing.

- Use of development technologies, such as Arduino.

Although the manufacturing techniques for prototype pre-series are handcrafted, it is very important to pay attention to the aesthetic finish, as it could influence the user experience in commercial experiments.

Although it is often seen as a minor detail, it is important to care for the way pre-series units are delivered. The user experience of a product starts with the packaging.

At Let’s Prototype, we have the ability to manufacture innovative packaging that adds a sense of final product to the pre-series units.

The pre-series units undergo evolutionary development processes. The knowledge gained from the use of pre-series units of a prototype should be translated into new functions, improvements in industrial design, and change decisions that simplify the future industrial manufacturing processes of the final product.

Most inventors and companies that develop products rely on their vision of the ergonomics of the products. The truth is that the best decisions about ergonomic designs can be derived from the commercial experiments conducted with the pre-series units of a prototype.

Certifications, such as the CE Marking of a product, should only be done on the final product units. However, the pre-series units of a prototype can undergo preliminary testing that provides valuable insights to minimize investments in necessary changes to obtain the required certifications to begin product commercialization.