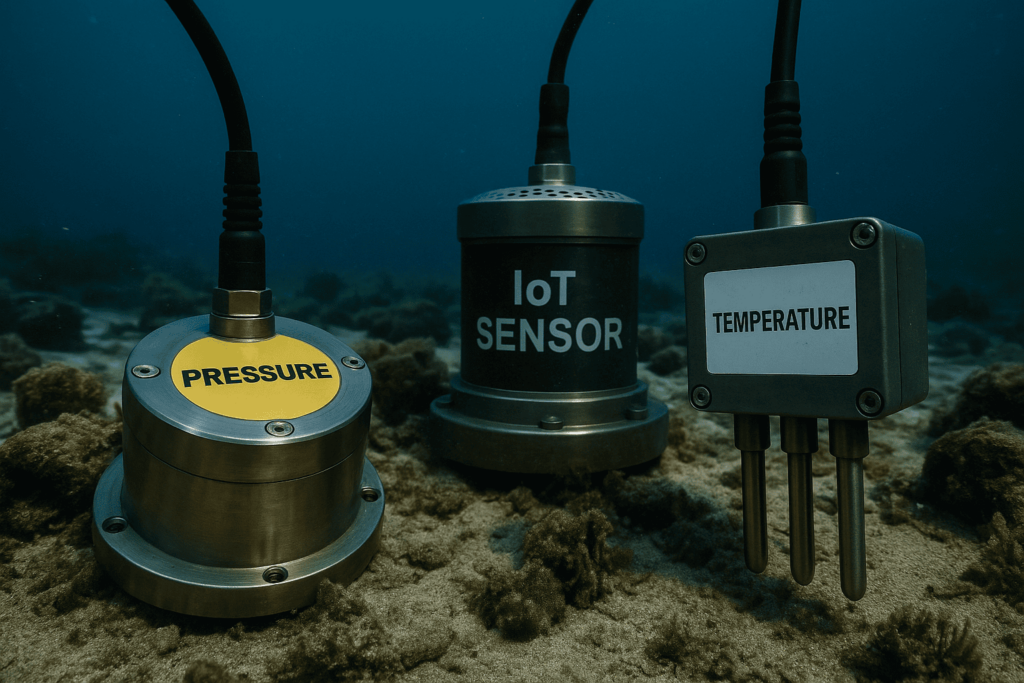

IoT technologies have become a common denominator in many instruments and tools for scientific analysis across various sectors. Below is our analysis of potential challenges of IoT devices in data collection.

Although the truly newsworthy event is the identification of slow and shallow displacements in the Nankai Trough, published in Science magazine at the end of June, at Let’s Prototype, as IoT product developers, we cannot overlook the potential technical challenges involved in the development of marine borehole sensors.

Hermeticity: We consider achieving perfect hermetic sealing in this device a key challenge for the development of the IoT sensor for marine borehole analysis. The device must withstand pressures that can exceed 50 MPa, so protecting the IoT device’s electronics is a critical mechanical challenge for its proper functioning.

Materials: Given the harsh conditions of the seafloor, in addition to the high pressure the marine seafloor analysis IoT sensor must withstand, the selection of materials for encapsulation is a key challenge. The device must endure prolonged exposure, which puts its integrity at risk due to potential corrosion and micro-fractures caused by such pressure.

The balance between size and energy autonomy is a key technical challenge in the development of any IoT device. In most of the prototypes built in our lab, this becomes a critical point of focus, for which we have developed an analysis environment for IoT product compartments, capable of revealing power consumption by state and thus designing a behavioral strategy through the electronic control software.

In addition to these challenges common to generic IoT devices, this specific case presents the nearly impossible accessibility to the IoT sensor for battery replacement or recharging.

In most IoT sensors used for analyzing movements on the seafloor, it is necessary to implement a captive power supply strategy. In other words, a cable is extended from the location of the IoT sensor to a floating buoy, which is typically equipped with a charging system that combines various methods of energy generation and storage.

The IoT sensors are primarily designed to capture and transmit data that can later be stored and interpreted for various functions. In this specific case, the movement data is displayed and sent to data analysis centers, where it is assessed to determine whether the behavior of the seafloor plates is normal or not.

Clearly, the data transmission process is a critical challenge, considering the characteristics of the environment where data is collected. For this reason, one possible solution would be to establish a wired connection to the floating buoy, which is necessary to address the challenges of energy autonomy and to transmit the data through this route to the surface. From this point on, the data transmission alternatives increase substantially.

In 100% of IoT devices, carrying out a proper calibration process is essential before deploying technological solutions and IoT sensors. For example, in IoT products developed in our lab—such as IoT shelves for retail, IoT dog collars, padel court devices, and IoT devices for agriculture—a calibration cycle of the captured data (temperature, location, weight, etc.) is performed prior to deployment. This ensures accurate measurements of the environment being monitored.

In the case of IoT sensors for seafloor environments, achieving precise calibration before deployment is not simple—mainly because simulating the actual conditions can be a real challenge.

Most IoT devices capture and transmit data that enables continuous monitoring, ultimately leading to the detection of an event. Determining the accuracy or validity of that event based on the captured data is a real challenge in most IoT solutions.

For example, IoT shelves for retail environments, which can detect when a specific type of product needs restocking, must accurately determine the minimum and maximum quantities to maintain. This is critical so that the device itself can send alerts after a simple analysis.

In the case of dog collars with event detection that aims to protect the animal’s health, it is critical to identify both the ambient temperature and the dog’s body temperature, as well as its current activity level. Alerts are defined based on a state determined by the combination of these variables.

There is one fundamental decision in the development process of an IoT device: Where should the variables be analyzed to determine the event?

In the case of IoT sensors used to analyze behaviors on the seafloor, two approaches can be taken. One is to implement a hardware unit on the floating buoy, capable of receiving the variables and analyzing them to determine when a noteworthy event occurs and when it does not—triggering additional data transmission only when necessary. This strategy is commonly used to optimize energy consumption, as the connection required to transmit data is critical in most IoT solutions.

Another possible strategy would be to send the full data streams to the floating buoy and, from that point, perform scheduled transmissions to the data analysis centers, which are responsible for running their mathematical models to determine predictions and behavioral patterns.

There are always multiple paths when designing and developing an IoT prototype. For this reason, before taking the first step, we recommend conducting a technical study to compare these alternatives—not only in terms of technical feasibility, but also to identify the best approach for creating a product that can evolve in functionality over time, with the lowest possible cost.

If you have an innovative idea for an IoT product, we’ll be happy to assess its feasibility in advance and address the different challenges that may affect the product design.