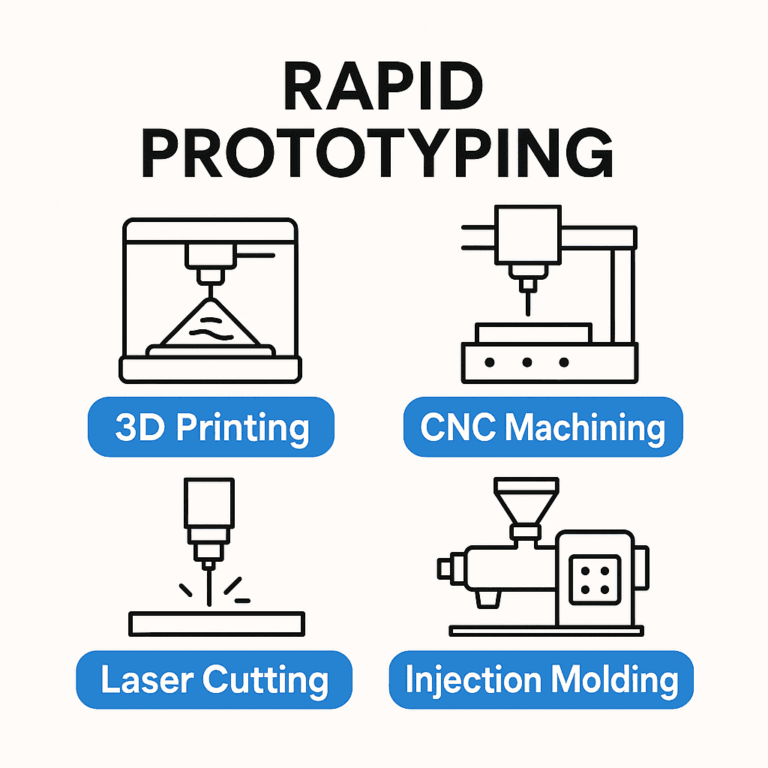

Erick Remedios lleva más de una década vinculado al emprendimiento, la inversión privada y el lanzamiento de proyectos innovadores. Inició su trayectoria en Business In Fact, S.A., red de inversores privados especializada en inversiones de alto riesgo, donde evolucionó hasta Director General, participando en más de 40 operaciones de inversión y asesorando a emprendedores e inversores en fases tempranas. Desde 2012 ha participado en foros de inversión, ha colaborado como asesor y miembro de Consejos de Administración, y ha desarrollado una labor docente y divulgativa en universidades como Universidad de Sevilla, Málaga, Cádiz, Granada, Pablo de Olavide, Huelva, Almería y Jaén, además de escuelas de negocio como IT Aérea Business School (donde lidera el módulo de Diseño de Modelos de Negocio) y ENyD. A lo largo de su trayectoria ha asesorado startups y compañías como Baby Radio, Neurobia Research, HitsBook, Bit Credit, Tu Fábrica de Eventos y Graffos, entre otras. Actualmente dirige la expansión internacional de Let’s Prototype en Estados Unidos y acompaña a empresas e inventores en el diseño, prototipado e industrialización de productos innovadores (hardware y software), así como en estrategias de comercialización y licenciamiento.