Let’s talk about your project

We’re aware of the importance of protecting information. It is for that reason that we only ask you for superficial and basic details that will allow us to assign your project in-house.

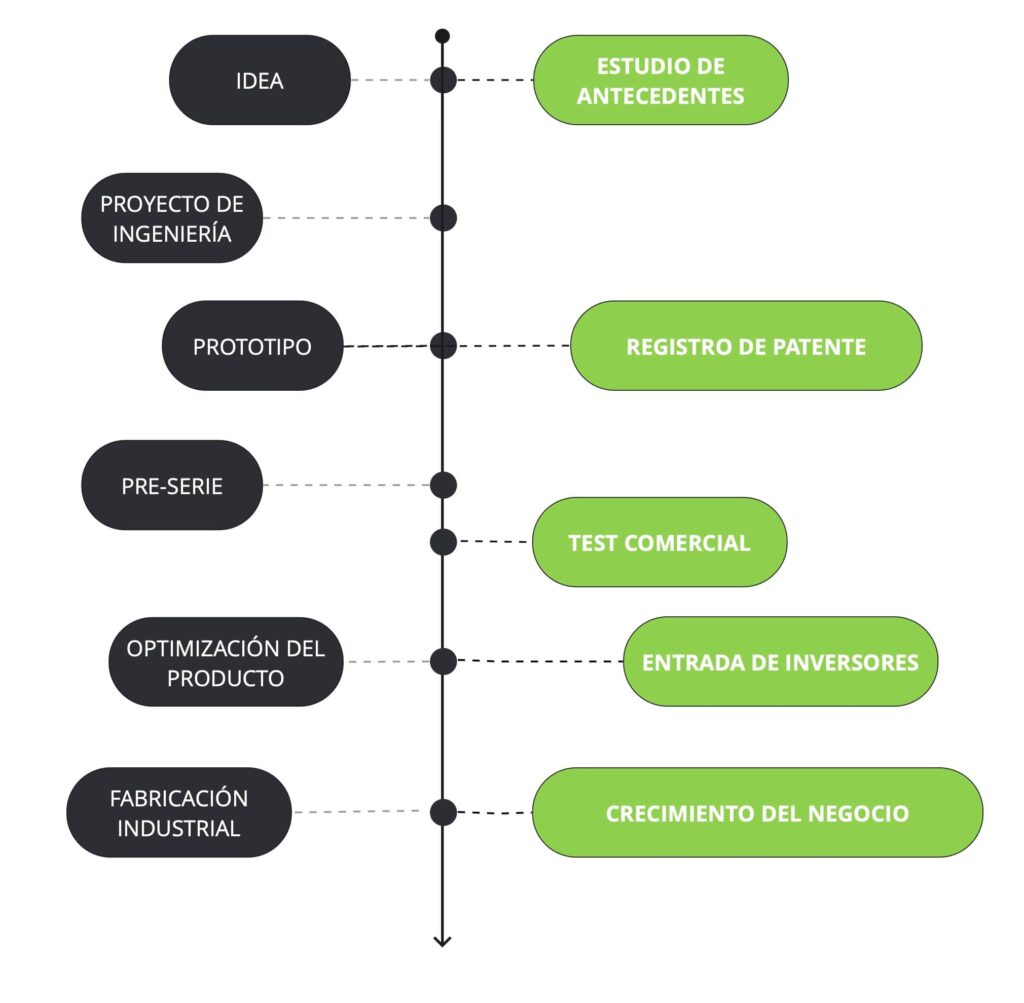

We present 11 steps and a proven method to create innovative products and inventions.

Let's talk about your invention

Book Appointment

Examples of innovative prototypes

Would you prefer us to call you?

Our experts will call you within the next 24 hours.

We analyze the necessary steps to turn an idea into a winning product. We also reveal the 3 mistakes that sink over 90% of inventors.

The guide of steps to develop a product innovative that we share does not come from textbooks.

This is a method built from the successes and failures experienced alongside inventors and innovation departments over more than a decade.

The innovation process begins with an idea or concept aimed at solving a problem present in the market.

New invention ideas are the spark that ignites the product development process.

Ideas are neither good nor bad. The success of ideas depends on the strategy, rigor, and effort that supports them. Ideas are neither good nor bad. The success of ideas depends on the strategy, rigor, and effort that supports them.

Before taking the first step, make sure the problem you’re trying to solve isn’t just in your head.

The first mission of an inventor or a creative team with a product idea is to understand the process and define a strategy. Any immediate investment will be money wasted.

Excessive love for the idea leads to failure. We rely so much on the idea that we overlook the need to understand the process. Ninety percent of inventors fail due to a lack of strategy rather than the quality of their ideas.

The background study of an invention is a very intensive investigation that allows you to learn:

The best professional in the world to conduct background research on an invention is the inventor themselves. No one will carry out such a thorough investigation, nor make better use of this process, than the promoter of the idea.

The engineering project is a theoretical‑practical investigation carried out in product development laboratories.

The main objective is to validate the technical feasibility of the invention. But it’s not the only one.

Products also need to be economically viable.

Specifically, the engineering project allows:

The engineering project, far from being a superfluous expense, is the step that achieves the most savings in the innovative product development process.

In the innovation cycle, there are no shortcuts. Any savings you achieve by altering the order of the steps multiplies the cost of later steps or condemns the product to failure.

In the prototyping phase, the main conclusions of the engineering project (Step 3) are materialized.

In the technical study, the main decisions about the product’s future are made, but it’s undeniable that adjustments and initiatives arise during the fabrication of the zero prototype.

The functional prototype is the physical demonstration of the product’s technical feasibility. Iterations on the first prototype provide highly useful insights to minimize the costs of the subsequent steps in the development of the invention.

There are two situations that undermine the prototyping process. Unfortunately, they are very common: manufacturing prototypes of patented inventions and improvising during the manufacturing process.

The dream of inventors is to patent a product and monetize the patent through its sale or licensing.

The pursuit of this dream without knowledge of the steps to create an innovative product and the lack of rigor of some advisors lead inventors to their worst decisions:

Patent too early.

There are two realities that demand your common sense: ideas cannot be patented, and patents cannot be edited. Therefore, if you file a patent before going through a serious process of innovation and development, you’ll end up with a mediocre and inaccurate patent.

Pre-series units are replicas of the best functional prototype we can achieve in the process.

Neither your vision is perfect, nor do the decisions of the product development experts have to be 100% correct.

No new product survives the first market shock unscathed. It's necessary to learn from users and fine-tune the product before going to industry.

The market rules, and you'll have to adapt your invention to its demands. The later you listen to it, the more money you'll lose in the process. Taking a prototype to industrial manufacturing is a disaster that costs tens of thousands of dollars and leaves many companies without options.

Product testing is a cycle of analysis on user behavior with pre-series units. (Step 6).

The goal of this process is not to make money, but to learn the adjustments that will allow for a better fit: "product - user"

Many inventors choose to move from prototype to industrialized products. This decision reduces flexibility and puts tens of thousands of dollars at risk.

Moving from prototype to production without actively listening to users can only be a symptom of ignorance or overconfidence in the product. Regardless of the cause, it's a mistake that can ruin the project.

The optimization cycle is a process of adjustments to the design and operation of the product.

The adjustments to be implemented at this stage are not the whims of the inventors or developers. They should come from two possible sources:

Early marriage with the industry often conditions the creative process and therefore limits the competitiveness of the product.

Most inventors, startups, and creatives raise private funds from local sources during the innovation process (engineering, patents, prototyping).

In these early stages, it's almost impossible to attract professional investors. The perceived business and technological risk makes it a bad deal for everyone.

Once the product has been fine-tuned and data demonstrates market interest (Step 7), the perception of risk is diluted, making it an ideal time to attract professional investors or more professional sources of resources.

Trying to attract professional investment prematurely will cost you dearly. There are reputable sources (FFF) that often support you in these early stages. With relevant data and technology ready for industrialization, it's the perfect time to accept investment.

The industrial manufacturing of an innovative product takes place in factories with the capacity to produce thousands of units in short periods of time and with very controlled costs.

Costs per unit manufactured can be decisive in a product's chances of success. For this reason, choosing an industrialization strategy that skips previous steps often leads to disastrous results.

The business of large factories is profitable when their machines don't stop. If, to shorten the process, you design and prototype in-house, you can be sure that the result will be compatible with their resources. Innovation within the industry condemns the final price of the product before it even begins.

Let’s talk about your project

We’re aware of the importance of protecting information. It is for that reason that we only ask you for superficial and basic details that will allow us to assign your project in-house.

Overconfidence in ideas, ignorance of a clear, step-by-step method for developing a new product, and irresponsible motivations on the part of so-called experts lead to alarmingly frequent errors.

More than 60% of inventors believe that patenting their idea brings them one step closer to making their invention profitable.

It is absolutely false:

We must not forget that the success of an innovative product is conditioned by its balance between technical and economic viability.

Going from idea to prototype is practically possible, but this path ignores a cycle of research and development that is essential before materializing the idea.

Discovering opportunities for improvement, which could impact a product's functionality and future costs, while it's being manufactured is less likely than when a dedicated research period is opened for this purpose.

Skipping the R&D&I cycle is an immediate saving that you will end up paying much more for in the product's industrialization cycle.

Depending on the rigor of the engineering project and adjustments to the functional prototype, the result may be closer or further from industrialization.

Regardless of this proximity, before bringing a prototype to the industry and undertaking the investments this entails, customers must be listened to.

The production of a pre-series of an invention and its observation cycle is one of the most enriching exercises in the process of creating an innovative product.

The time to bring your ideas to life is now. We accompany you throughout the entire process: from idea to product.

San Juan Ingenieros, S. L, is the owner of the domain www.letsprototype.com, and in accordance with the General Data Protection Regulation (EU 1679/2016), we will process your data exclusively to handle your information request. You have the right to rectify or request the deletion of your data at any time via hello@letsprototype.com.