3D printing techniques. Rapid prototyping manufacturing.

As we explained to our community of inventors, 3D printing is not the same as manufacturing a working prototype. In fact, 3D printing techniques are only part of the manufacturing process of a prototype.

3D printing techniques allow to accelerate the innovation process, facilitating the realization of countless proofs of concept. As you know, the ability to iterate is key to getting the best possible functional prototype.

As 3D printing techniques become so relevant, from the technical team of Let's Prototype we will make a very brief and practical summary so that you can understand the most democratized options in the market, of course, also available in our prototype design and manufacturing laboratory.

What are the most popular 3D printing techniques?

- Fused deposition modeling. Better known as FDM.

- Stereolithography. Better known as SLA.

- Sinterizado Selectivo. Conocido popularmente como SLS.

What is Fused Deposition Modeling? (FDM)

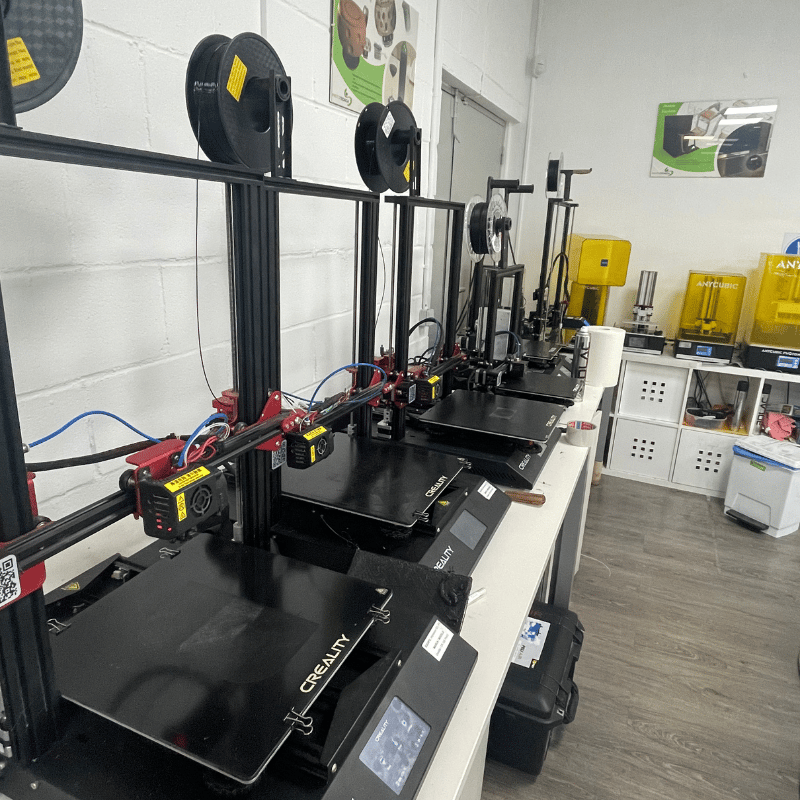

FDM is the most democratized 3D printing technique on the market. It is the printer that comes to mind when the term is mentioned.

This type of 3D printers make up the pieces while feeding on plastics in the form of filaments, like a kind of thick thread, which goes through a hot extruder that places the material through points, layer by layer, until the construction of the pieces is achieved.

The reality is that, in a few hours, almost any type of part can be built, useful for testing concepts and finding substantial improvements over functional prototypes.

In Let's Prototype we have tested multiple models of 3D printers (FDM), the truth is that, although it seems to build parts autonomously and accurately, the reality is different:

- It requires continuous maintenance, although they are very cheap.

- It requires manual calibration processes and artisanal techniques that minimize tolerances, so that it manufactures parts as similar as possible to what we require through design.

- Achieving good results with this type of machine requires experience modifying the optimal configurations for each material. The relationships manufacturing time and resulting quality is critical.

- The resulting parts are not very accurate, therefore, to test concepts that require precision, the experience of the designer who manages the printers is essential.

- The finishes are not very aesthetic, in Let's Prototype we have developed methods and techniques of post-processing of parts, in this way, we manage to improve the mechanical resistance of the pieces as well as their aesthetics.

Although it may seem that we are enemies of FDM 3D printing techniques, nothing is further from reality, it is part of our day to day and after almost a decade working with them, we combine them with others such as SLS, SLA as well as with the manufacture of wooden molds, silicone, among others.

What is Stereolithography? (SLA)

Unlike FDM 3D printing techniques, the SLA is fed with liquid resins in a kind of pool. From the lower surface of the tank, laser light points are applied that cure said resin, until the change of state, from liquid to solid, of the different resins is achieved.

In Let's Prototype we have tested multiple models of 3D printers (SLA), the truth is that today, we manufacture with this technique, very small parts with very high levels of precision and large format parts, with the same level of accuracy between the result and the design.

According to our experience, about the SLA we can tell you that:

- The resulting parts must be cured and washed. Although we use some commercial machines for this, the truth is that for large pieces, we have manufactured some handmade tools that facilitate the work.

- As a very favorable point, there are countless materials and combinations, with which optical effects such as transparency are achieved. With these techniques, in Let's Prototype we have achieved parts with hypoallergenic characteristics, biocompatible, etc ...

- The mechanical resistance of the resulting pieces is very compromised, for this reason, in Let's Prototype we have developed artisanal methods that allow welding the pieces and maximizing their mechanical resistance.

- The exchange of materials to get different pieces is not so simple, it requires a deep cleaning of the tank, filtering of the resin among other artisanal processes for which I recommend, space, protection of surfaces and especially of your clothes.

- With the techniques of 3D printing, SLA, in Let's Prototype we manufacture useful molds for other manufacturing techniques of useful parts for our functional prototypes.

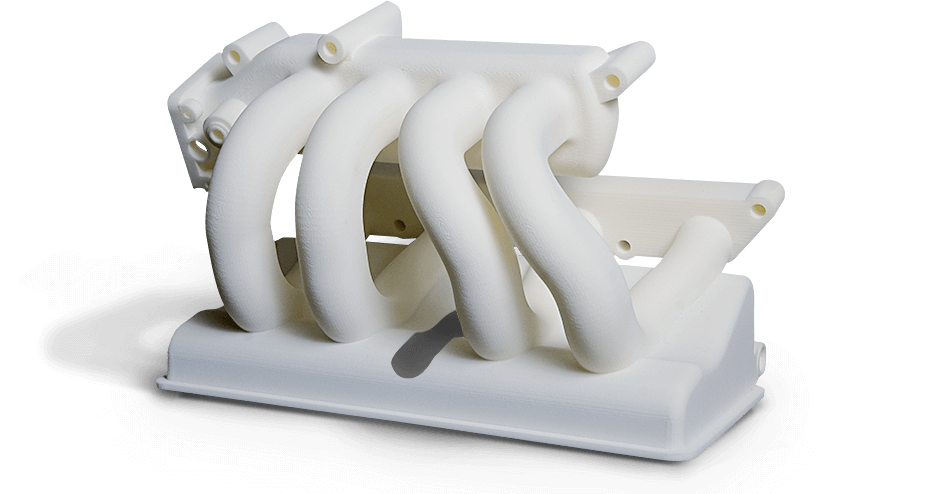

What is Selective Sintering? (SLS)

Although the techniques of 3D printing, SLA and FDM, analyzed above, offer compromised mechanical resistances, the truth is that Selective Sintering or SLS, comes to solve this commitment.

Remember that in the case of FDM and SLS, the adhesion layers that confirm the pieces, start from the filament extrusion or solidification of the liquid resin respectively. In the case of SLS, the parts are formed through the powder function with a very powerful laser.

As main advantages and disadvantages of this technique, in Let's Prototype, we highlight that:

- Without a doubt, SLS is the best technique to achieve the manufacture of parts with complex shapes.

- By offering better results in terms of the mechanical resistance of the parts, it is optimal for parts with thin walls as well as complex geometries in interiors of the same.

- It is relevant to note that the manufacturing times through the SLS are excessively long.

What is the best 3D printing technique available?

We found no better way to help you make decisions about printing techniques, than summarizing in a comparative table the experience of the design and mechanics team of Let's Prototype.

FDM | SLA | SLS | |

Precision | Regular | Very Good | Excellent |

Aesthetics | Regular | Excellent | Excellent |

Usability | Very Easy | Very Easy | Medium complexity |

Print speed | Speed | Speed | Low |

Costs | Low | Middle | High |

Mechanical Strength | Low | Low | High |

Although in this post we have described the most democratized 3D printing techniques in the market, the truth is that, in Let's Prototype we complement these techniques with artisanal processes, as well as cold molding techniques.

As a main conclusion, we must be clear that there are no good and bad 3D printing techniques, their selection depends on the requirements of each prototype and the objectives pursued with each one.

Recent Posts

Tell us your idea

- Apple Patent Conflict. Conclusions for Inventors - January 5, 2024

- How to register a trademark in the USA? - November 14, 2023

- How to obtain funding to launch a product to the market? - August 9, 2023